Language

Infolinka

491 841 364

EPE packaging

Plastic PE packaging is manufactured according to your requirementsto ensure that it precisely meets the requirements of further processing.

Due to its specific properties and variability, polyethylene foam has many applications in various industry sectors – these applications range from auxiliary functions, when it does not become part of the final product, to situations where the final product contains only polyethylene foam.

Polyethylene (EPE) is usually processed using the following technologies:

- laminating

- cutting

- trimming

- trimming strips to size

- hot forming

- some other types of processing which are developed according to your individual requirements

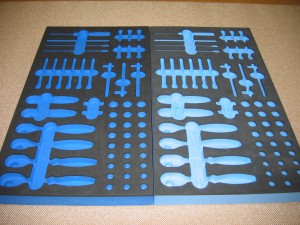

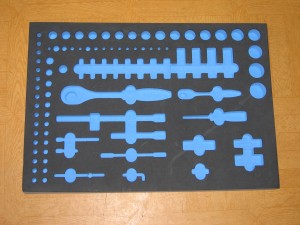

Tailoring the size and shape of PE foam

One of the most frequent customer requirements is to tailor the size of foam (partially in the form of the required strip width or board format and in detail in the case of the requirement concerning the specific shape of a product with a precise dimensioned drawing).

Foam hot forming is a more technologically demanding process the result of which cannot be usually achieved by any other technology. We usually use this method for manufacturing more demanding shapes of products, where special emphasis is placed on the quality of the final surface.

In the case of hot forming laminating foam together with textiles and subsequent hot forming and cutting are usually combined. This is a very fast and efficient method of manufacturing a semi-finished product intended for subsequent processing.

We use polyethylene foam for manufacturing:

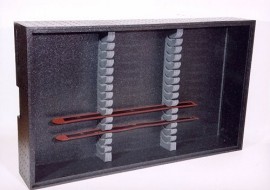

- complete transport boxes made of foam

- fittings

- layers

- fixing blocks

- dividers

- gratings, etc.

Menu

Menu